Introduction

Belt Wise manufactures and supplies conveyor belting engineered for harsh duty and critical maintenance windows. Each belt is specified for strength, safety and lifecycle, backed by QA documentation, MDR traceability and AI‑enabled inspection for splice verification. Rapid local dispatch across keeps production moving.

Product Range

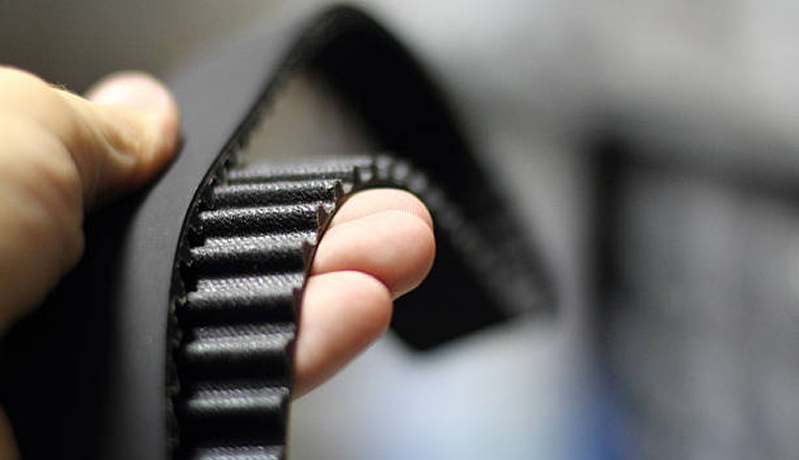

Rubber Products & Lining Systems

Load zones, transfer points and sealing interfaces demand the right rubber. We supply engineered rubber products that control impact, reduce spillage and extend belt life. Each item follows the same QA approach as our belts for durability, FRAS suitability and traceability:

- Chute lining systems configured for duty and impact conditions.

- Skirting systems and scrapers to limit carryback and housekeeping.

- Wear and impact solutions for load points and transitions.

- Repair and adhesion kits to keep crews productive during outages.

Every belt is tracked, tested and delivered with QA documents, MDRs and full traceability. With over $1 million in Australian stock, emergency dispatch happens in hours, not weeks.

Conveyor Belts

Every operation faces a different challenge – heat, oil, abrasion or compliance. Belt Wise supplies proprietary belts from an ISO‑accredited production environment with advanced compounds and proven constructions. The range includes:

- FRAS‑rated belts for regulated underground and plant environments.

- Abrasion and cut‑resistant belts for mining, quarrying and heavy‑duty transfer. By utilising the ArmourFlex technology, these belts combine extreme impact absorption with reinforced flexibility – ideal for high-drop loading and primary crusher applications where durability and load stability matter most.

- Heat‑resistant belts for sustained high-temperature service, featuring Heat Seeker-OR compounds engineered to withstand continuous heat and oil exposure up to 220°C, while maintaining tensile strength and long-term elasticity in asphalt, cement and processing environments.

- Oil‑resistant belts for fertiliser, grain and process lines with hydrocarbon exposure.

Custom compounds formulated for site‑specific duty and environmental goals.

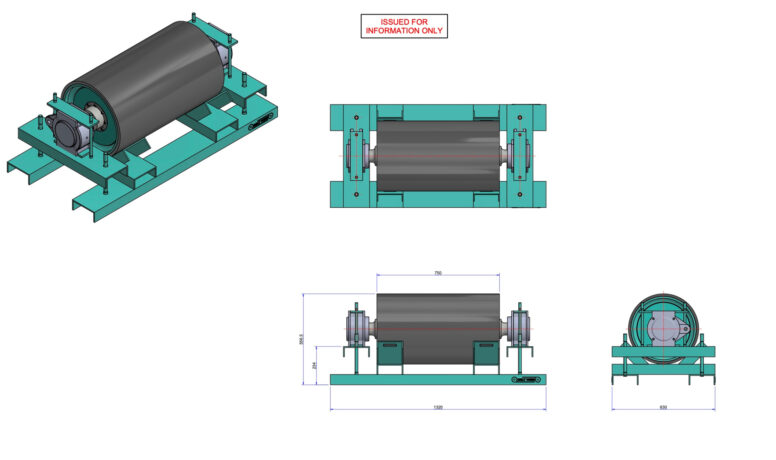

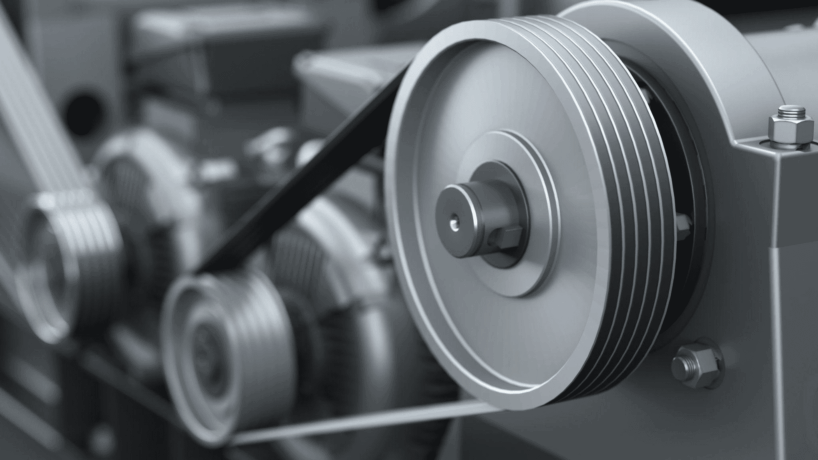

Pulleys

Precision-Made for Continuous Operation.

- Drive and non-drive pulleys designed for high-load performance

- Lagged and non-lagged options for optimal traction

- Manufactured to exact balance standards to reduce vibration

- Compatible with Belt Wise belting and mechanical systems

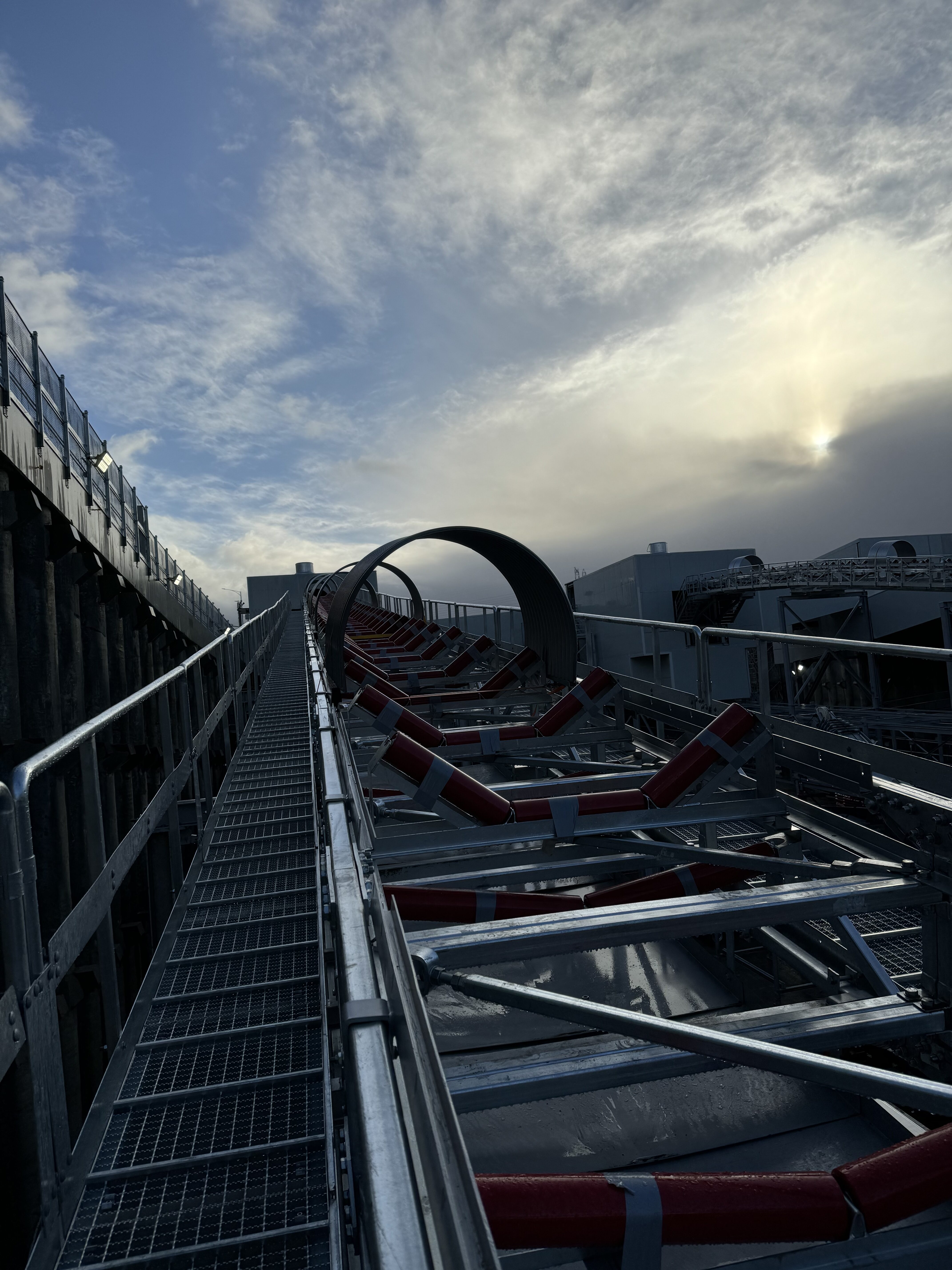

Gallery

From mine sites to export terminals, Belt Wise belts and components perform in real conditions. Explore our installations, manufacturing facilities and 3D product renders to see how we build reliability from the ground up.

Solutions That Fit

Your Industry

Mining & Resources

Heavy-duty abrasion-resistant belting and lagged pulleys.

Ports & Infrastructure

Fire-retardant and oil-resistant belts for export terminals.

Processing & Manufacturing

Custom belts and pulleys for production lines.

Agriculture & Bulk Handling

High-traction pulley systems and oil-resistant belts.

Quarrying & Construction

Impact-protective rubber lining for harsh environments.